Injection Moulding Machines

Injection Moulding Machines type of Products to be made Commercial / Industrial / Automotive / Aerospace Power-tool housing, Disposable razors, the versatility of injection moulding is facilitated by our modern design.

View More ![]()

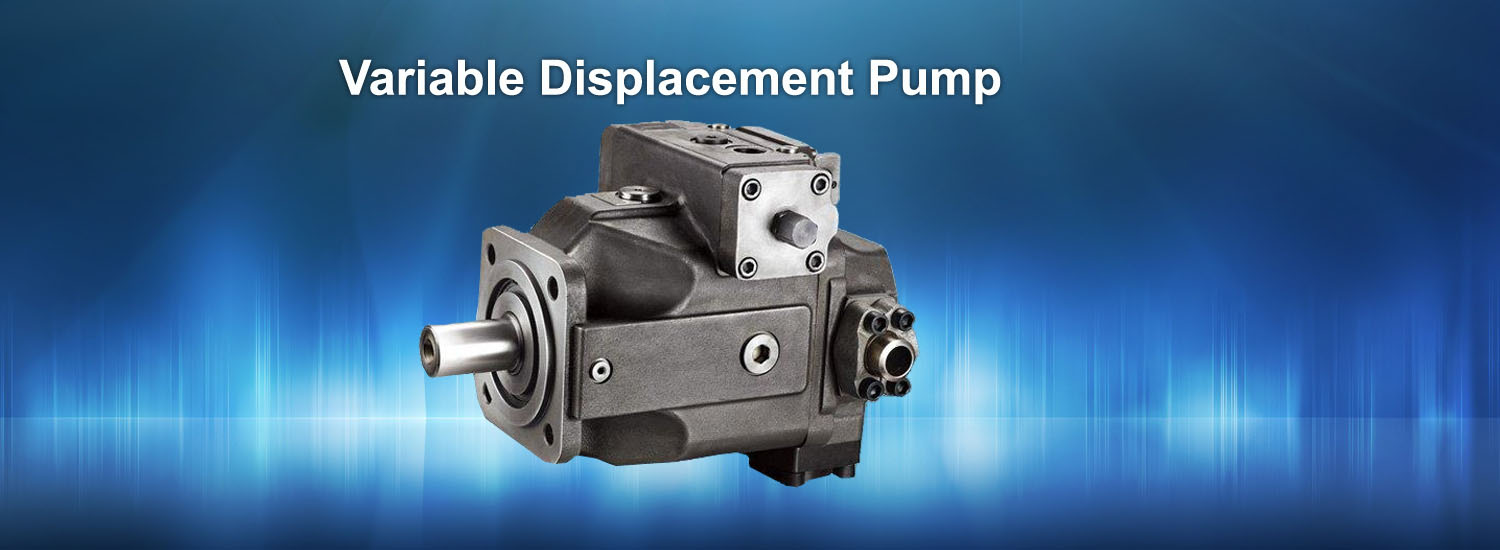

PET Preform Injection Moulding Machine

PET series Toggle Injection Moulding Machines are designed with CAD optimized high speed, five point twin toggle locking mechanism

View More ![]()

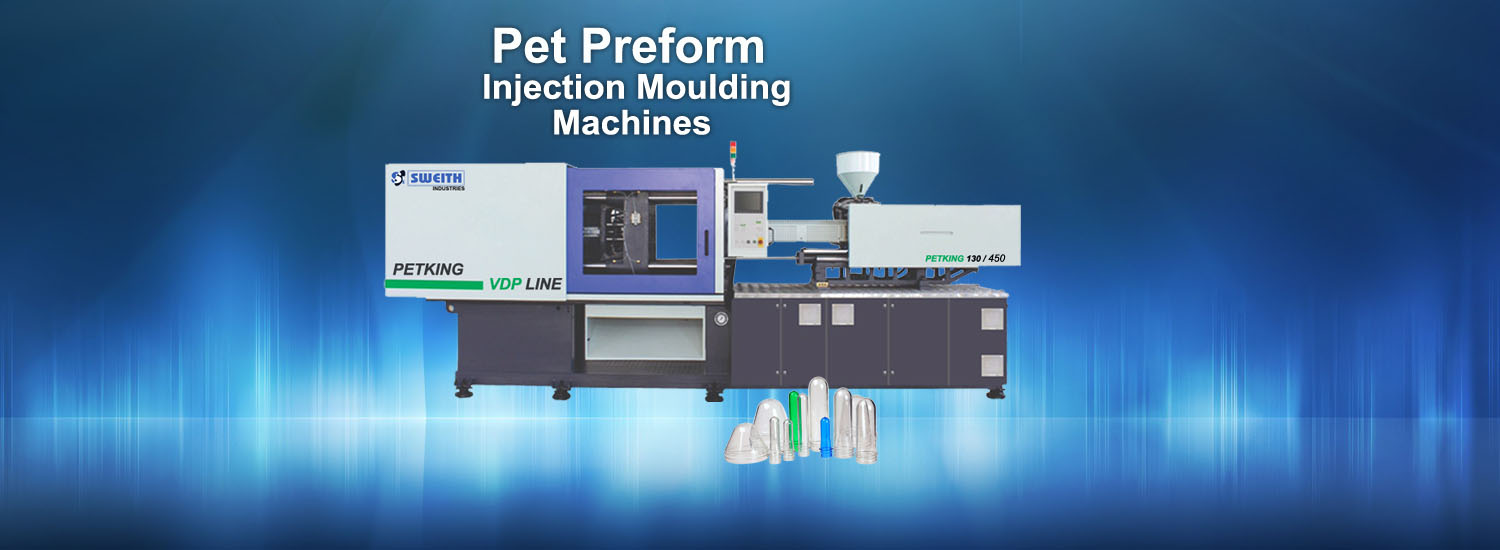

RPVC Injection Moulding Machines

RPVC series Toggle Injection Moulding Machines are designed with CAD optimized high speed, five point twin toggle locking mechanism.

View More ![]()

Welcome to

The Sweith Industries!

we stand on the line of reputed manufacturers of Thermoplastic Injection Moulding Machines, Established in 2005 at Gujarat's Engineering Hub City Ahmedabad, we have successfully made our reputation to stand aside as a leading supplier along with manufacturer of the Plastic Injection Moulding Machines in Ahmedabad.

Read More